본문

Introduction purpose

- Establish a system to self-diagnose the faulty part of the production facility in the system to find the faulty part and cause, and link this information with MES and ERP

- By monitoring the operation time of production facilities in real time and detecting minute changes, it is possible to analyze the causes of failures before they occur and to identify the state of the equipment, and when a failure occurs, the equipment is immediately notified of the cause. Establish a management system that allows maintenance workers to respond immediately

- Through analysis of failure patterns of production facilities, failure grades such as warning messages and heavy failures are managed, and repeatability is measured in real time, enabling rapid system diagnosis and accelerating failure response.

- Establish a management system that can efficiently identify the operation status of the manufacturing line in an unrestricted space through the monitoring system linked with the integrated MES

- Establish a prompt response system for process defects by monitoring the real-time cycle of production facilities to check the possibility of defects due to abnormal operation of the equipment

- Establish a management system to maximize the efficiency of the manufacturing line by collecting information such as the number of operation cycles of the manufacturing facility, whether the operation cycle is normal/abnormal, the contact points for the cause of the failure, and the repeatability of the failure (initial, continuous)

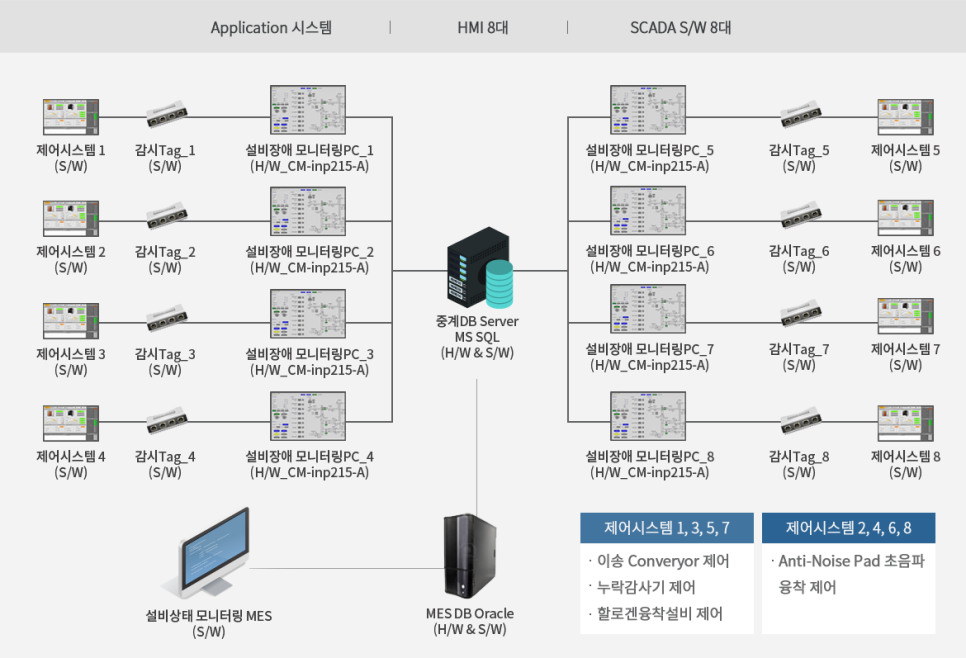

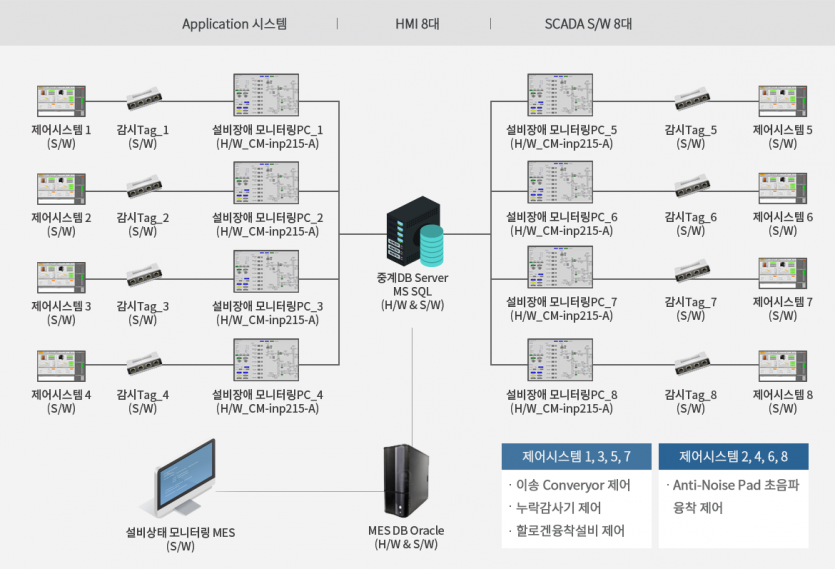

Introduction equipment

Introduction performance

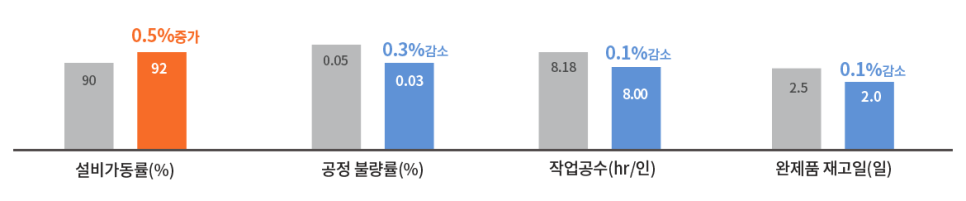

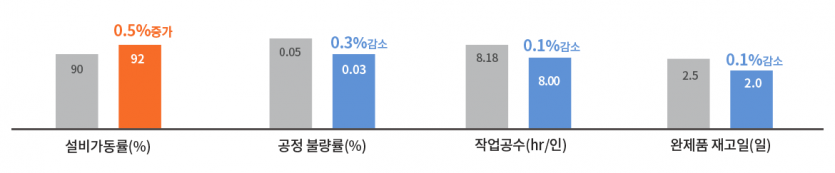

quantitative performance

qualitative performance

- Securing stable production site management by real-time monitoring and monitoring of production facilities

- Real-time production facility operation time management and facility self-diagnosis monitoring system enables visual production site management regardless of management location

- Raising awareness of quality in production sites through real-time facility operation information collection and analysis management

- Accurate and prompt collection and analysis of production facility failure and operation data is possible, preventing recurrence by identifying the cause of a problem

- Real-time production facility operation time management and facility self-diagnosis monitoring system enables visual production site management regardless of management location

- It is possible to establish an effective production support system by real-time management of global local factories through the production facility self-diagnosis MES system

- Rapid and consistent sharing of field data and speeding up

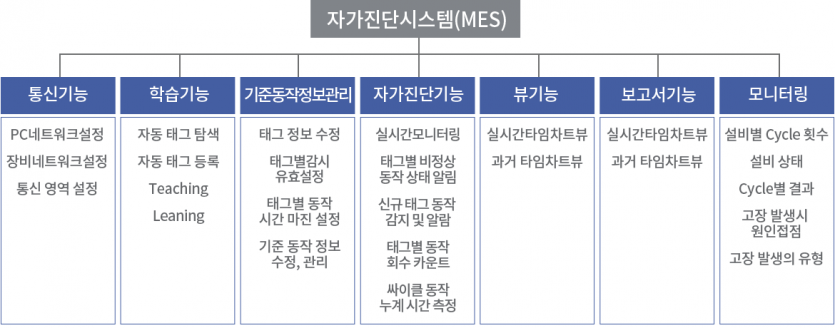

Implementation Application System

KOR

KOR