본문

Introduction purpose

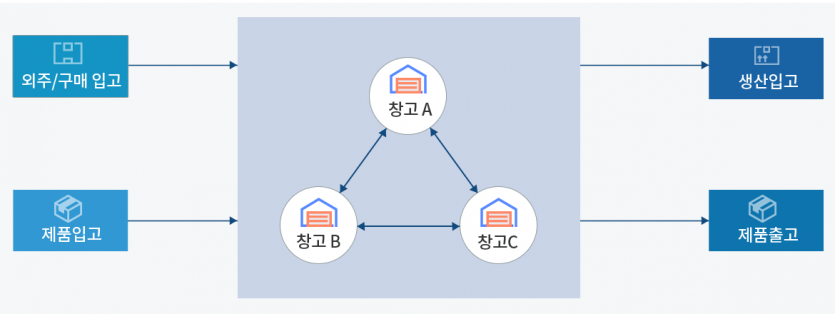

- Securing logistics management and operational capabilities by integrating and managing all activities that occur while managing logistics and materials/inventory within the material/inventory warehouse

- Quickly and accurately manage all warehouse operations (receiving, location, shipment, movement, inventory survey, etc.) and support real-time sharing of inventory information with supply channels

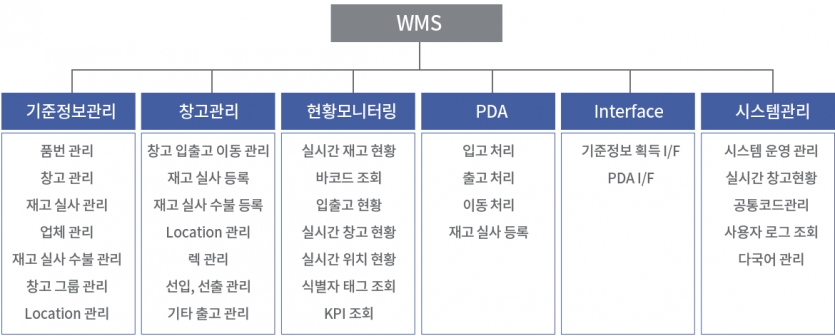

- Supports a new management paradigm as a practical platform for all activities performed in the warehouse by configuring warehouse warehousing management / inventory management / status monitoring / interface / POP

- Accurate and transparent performance management by providing shipment performance management through barcode system

- Quickly explore the inventory status, identify and manage the current status

- KPI indicator calculation

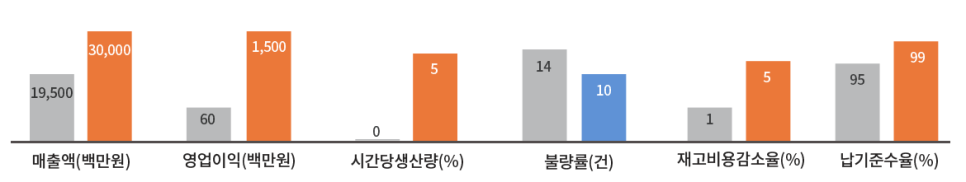

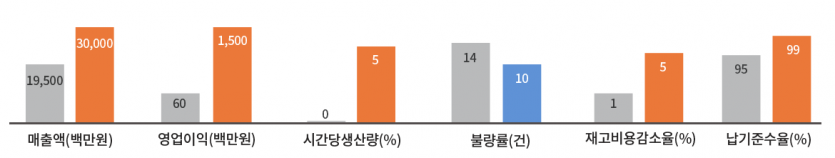

Introduction performance

quantitative performance

qualitative performance

- Process material and finished product warehousing based on barcode and PDA to automate inventory counting, shorten inventory counting time, improve inventory accuracy, and secure efficient management of warehouse space

- Barcodes and manages materials and finished products received in the warehouse to manage company-wide first-in/first-out, prevent unnecessary inventory retention, improve delivery compliance, and improve inventory precision

- Establish an environment where the person in charge can receive the materials and products they want through location and rack management after inquiring about location inventory management, providing visibility of inventory and product location information, and improving inventory precision through PDA or PC

Implementation Application System

KOR

KOR