본문

Introduction purpose

1. When a production plan is registered in the system, the work order and drawing information suitable for the production plan are displayed on the monitor of the field worker to strengthen the collaboration function and improve the management system

2. In the event of a failure in the equipment, check the equipment and type of failure in real time on the monitoring screen, and quickly prepare the relevant tools to respond to the failure

3. In the event of a quality problem, the monitoring screen identifies the type of quality problem displayed on the screen, and supports to move to the appropriate work facility to perform quality inspection

4. Implementation of an environment that manages operation time information, worker attendance information, production performance, and non-operation information, derives production utilization rate, cycle time, and capacity, and efficiently manages the distribution of facilities and personnel

Introduction performance

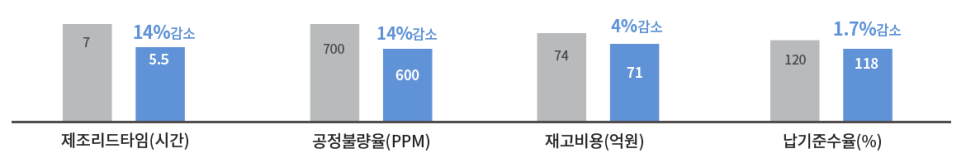

quantitative performance

qualitative performance

1. By providing the latest work order information and drawing information according to the production plan information, the possibility of defects that may occur due to incorrect work orders or drawings by field workers is minimized

2. Real-time monitoring of equipment failures, establishing an environment that can respond immediately in case of failure, minimizes loss of production time that may occur due to equipment failure, and maintains equipment by managing the types and history of equipment failures Improve your competencies.

3. From the aggregation of manual performance through multiple procedures using the existing work log such as Excel, through user performance registration through KIOSK, the performance information is aggregated based on the performance information registered in the system, Improving the accuracy of time and counting results.

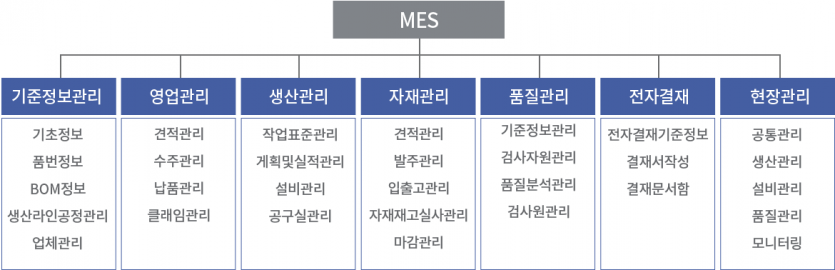

Implementation Application System

KOR

KOR