본문

Introduction purpose

○ By improving the existing manual-oriented work process, the cost is reduced through the reduction of work loss through the system.

○ When a production plan is registered in the system, the work order and drawing information suitable for the production plan are displayed on the monitor of the field worker, thereby strengthening the collaboration function and improving the management system.

○ In the event of a failure or non-operation, the status of the failure or non-operation is communicated to the person in charge of production management to resolve the failure or problem at an early stage

○ Prevent major obstacles by deriving the basis for establishing countermeasures for frequent non-operation and obstacles through statistics by obstacle factor or type of non-operation

○ In the event of a quality problem, it is possible to identify the type of quality problem displayed on the screen through the monitoring screen and to move to the relevant work facility to perform quality inspection.

○ Through monitoring of the production status, the status of each work site and process is identified in real time, and in case of an emergency, the work order is changed to suit the work site situation, etc.

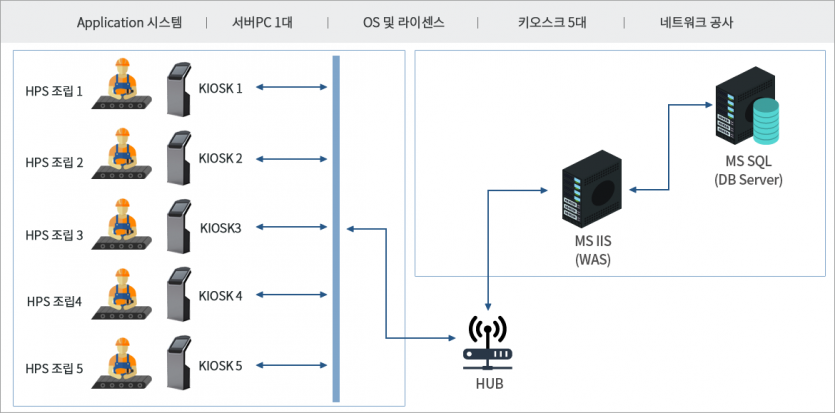

Introduction equipment

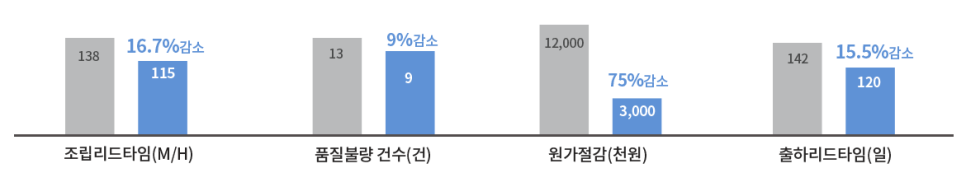

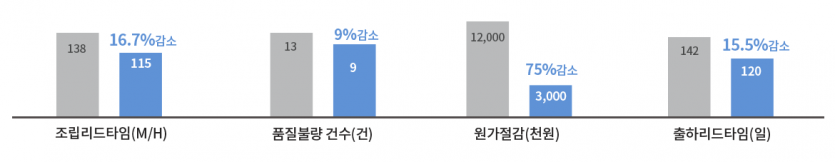

Introduction performance

Quantitative performance :Based on HPS 70ME model, cost reduction of drawing distribution and change management

qualitative performance

○ By distributing the latest drawings and work orders through the system, errors due to damage or incorrect distribution of drawings and work orders are minimized, thereby minimizing the possibility of potential defects, and checking the accuracy of drawings offline. minimize time

○ Regarding failures occurring at the work site, information is delivered to the person in charge of production management/quality/equipment maintenance in real time for each type of failure, and prompt response to the failure

○ For non-operation cases caused by quality problems and equipment failures, in particular, in the case of equipment, predictive maintenance of equipment is possible through statistics by equipment and equipment failure type.

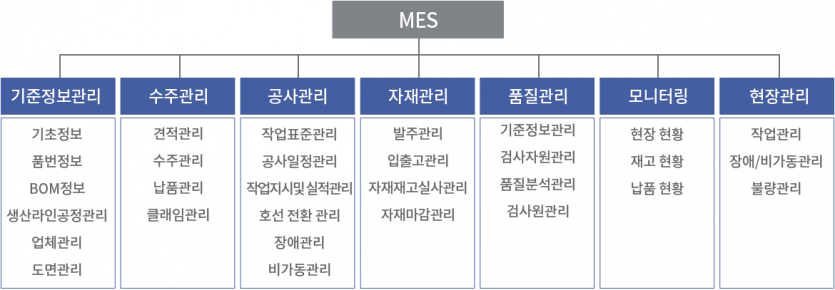

Implementation Application System

KOR

KOR