본문

Introduction purpose

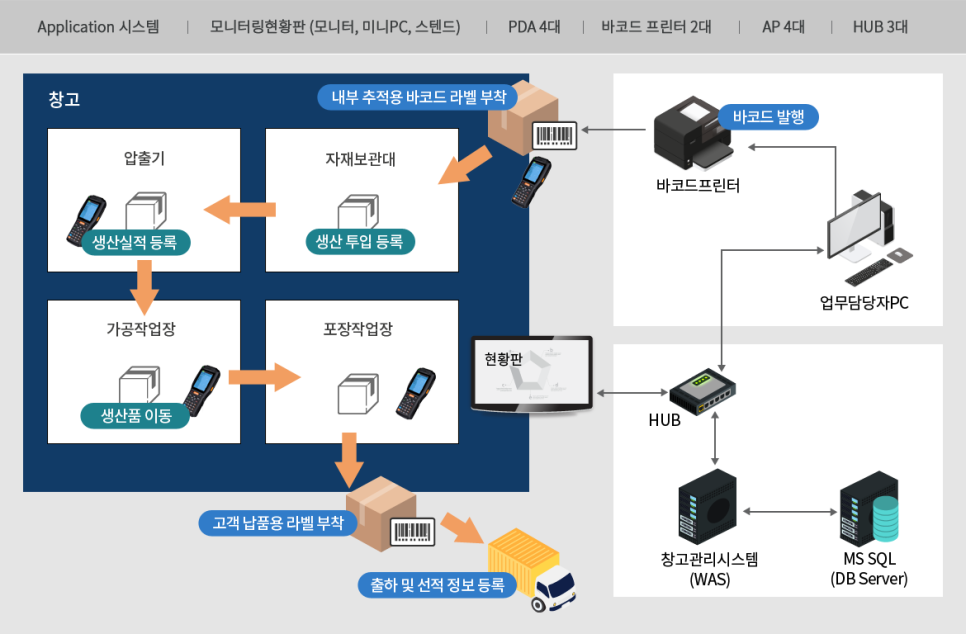

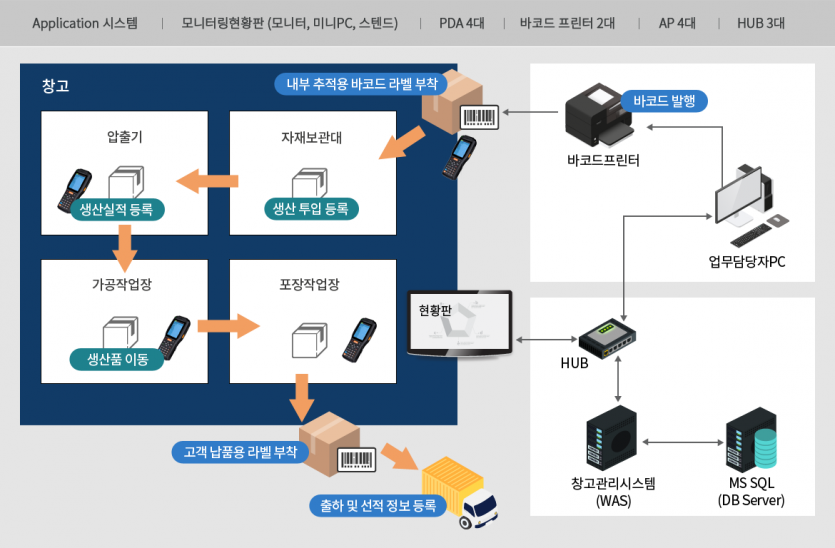

- In order to secure inventory and work efficiency, a system that can provide real-time inventory information such as management of material movement and shipment history of semi-finished and finished products and inventory identification by location (warehouse, zone, rack, etc.) is needed using barcodes

- By implementing a monitoring function that can identify current inventory, movement history, and location of inventory in real time, make better business decisions and utilize the obtained data as evidence for business expansion

- Real-time management and tracking of material movement and delivery of semi-finished and finished products

- Prevention of inventory loss due to storage for long-term storage and identification of pre-stocked inventory by utilizing the warehousing history and barcodes attached to the real thing when warehousing materials

- Through movement and location management of received materials and stock, it is possible to quickly grasp the work order of workers and secure

Introduction equipment

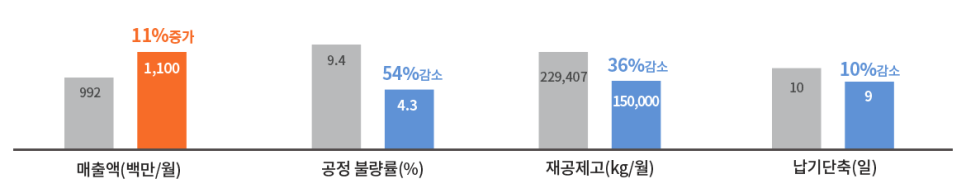

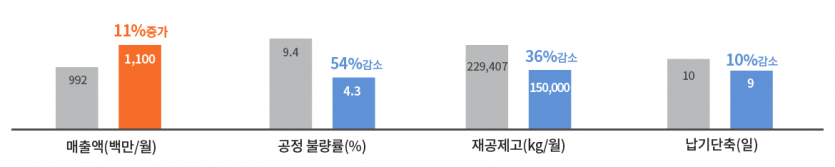

Introduction performance

Quantitative performance : Sales increase due to product reliability improvement, removal of defects caused by incorrect material input, reduction of rework by identifying malicious inventory, improvement of delivery capability

qualitative performance

- In order to check the tracking information of manufactured products, quickly inquire through system inquiry, not by phone or on-site inspection

- Quickly explore the inventory status to understand the current status

- Accurate and transparent performance management is possible by providing production performance management and shipment performance management through the barcode system

- As production data can be collected and analyzed accurately and quickly, recurrence is prevented by identifying the cause of the problem.

- Rapid and consistent sharing of field data and speeding up

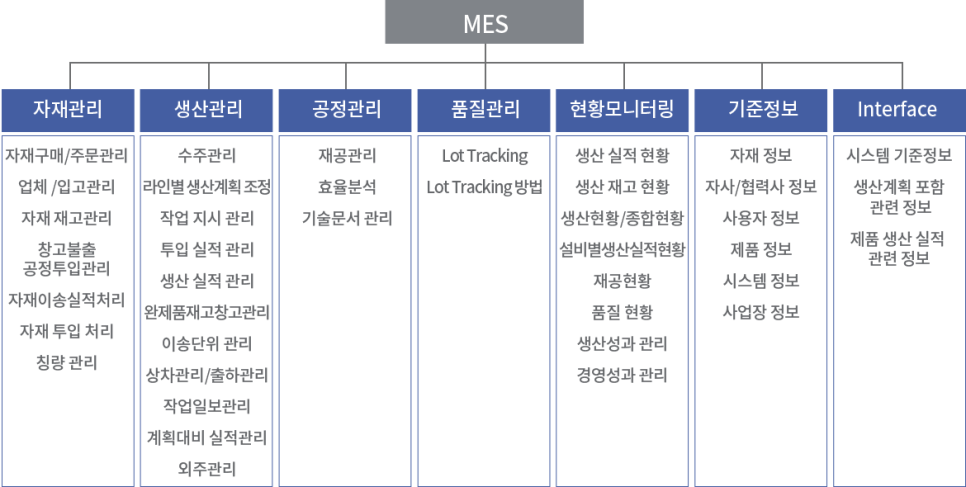

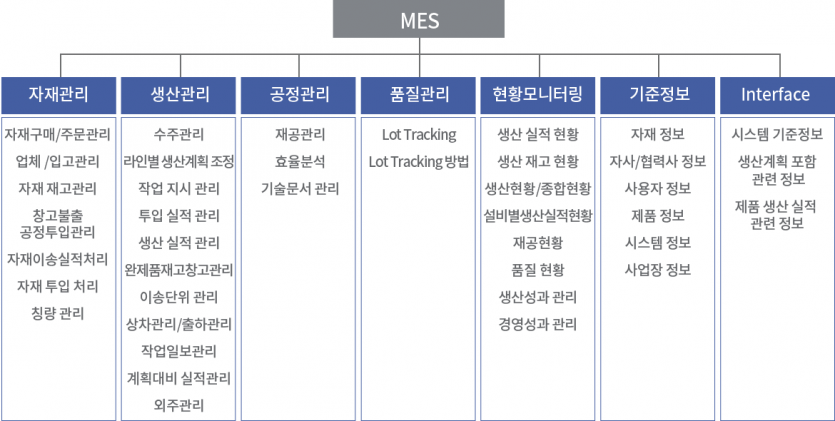

Implementation Application System

KOR

KOR