본문

Introduction purpose

ㅇ Lack of first-in/first-out management

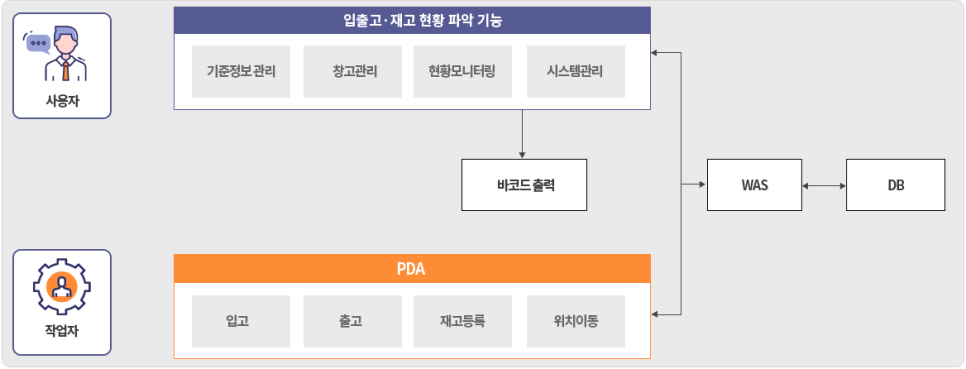

-> In order to improve inventory/logistics management and work efficiency in the warehouse, use barcodes to manage the history of logistics movement and shipment in the warehouse, identify inventory by location (warehouse, zone, rack, etc.) in real time, and manage the location by standard for each item

ㅇ Lack of inventory/product quantity management

-> Real-time response to merging or division when dispensing materials through barcode division, merging, and deletion functions

ㅇ Problems dependent on operating personnel

-> Implementation of monitoring and history management function that allows real-time understanding of current stock, quantity by stock, location, movement history, and location of stock

ㅇ Data reliability problem

-> Manage inventory/logistics-related information using barcodes to secure data accuracy that is far superior to existing manual management

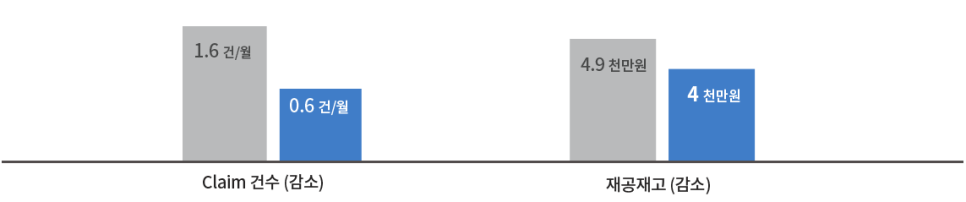

qualitative performance

ㅇ Stable warehouse site management by establishing a real-time monitoring and monitoring system for warehouse management

ㅇ Through the DFS-NWMS system, production performance management and transparent performance management are possible

ㅇ Accurate and transparent performance management is possible by providing shipment performance management through the DFS-NWMS system

ㅇ Checking real-time inventory information proceeds quickly with the system

ㅇ Quickly and accurately manage all warehouse tasks within the warehouse (receiving, location, release, movement, inventory due diligence, etc.), and support real-time sharing of supply channels and inventory information.

ㅇ Fast and consistent sharing of on-site data and expedited decision-making

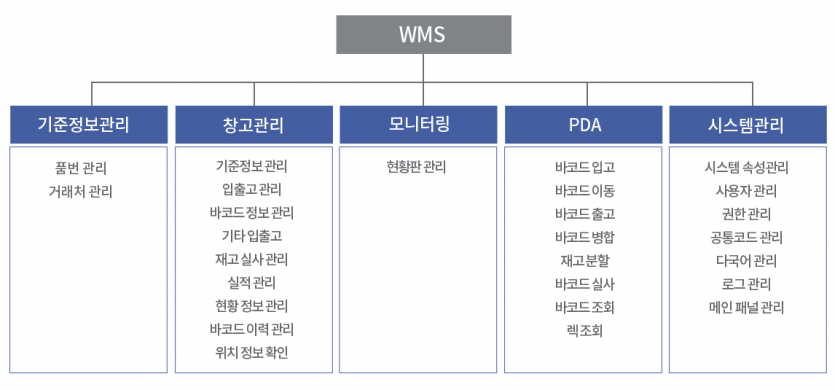

Implementation Application System

KOR

KOR