본문

도입목적

Introduction purpose

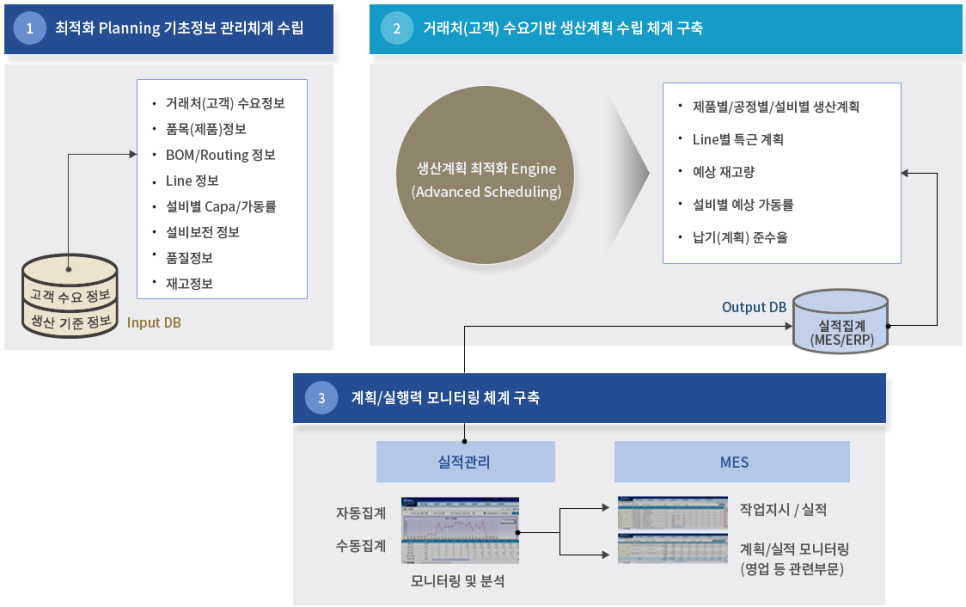

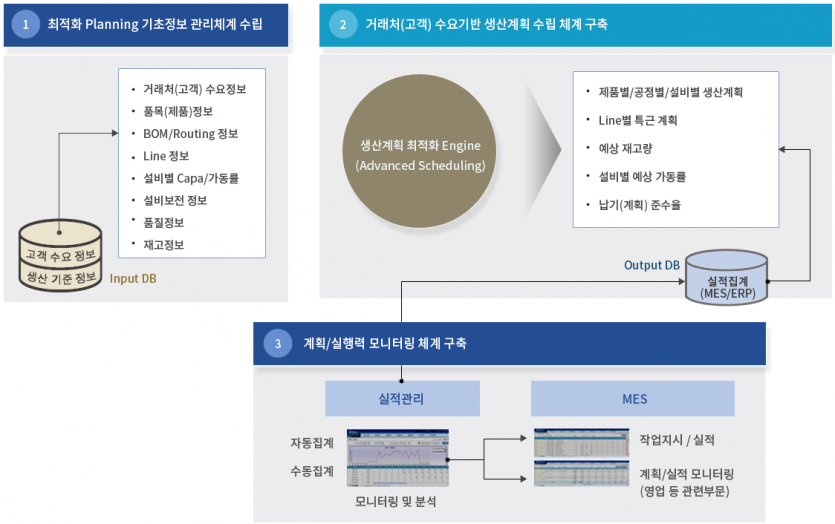

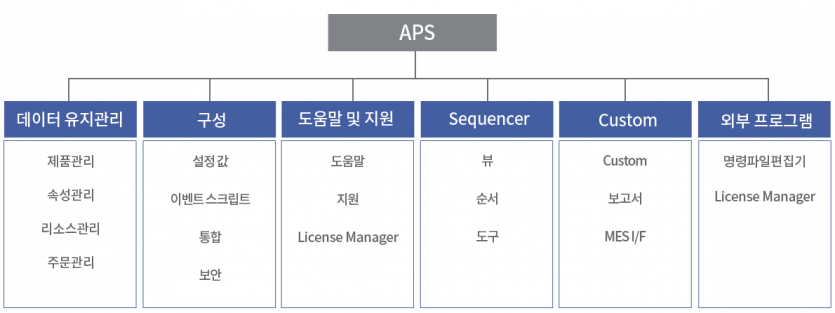

ㅇ Establish an optimized scheduling and basic information management system through standardization of customer demand information, shipment information, and detailed information of each product (BOM, Routing, Line, facility capacity, operation rate, etc.)

ㅇ Company-wide management of production plans for each product/process/equipment, overtime plans for each line, expected inventory volume, expected operation rate for each facility, and compliance rate for delivery (plan)

ㅇ Establishment of planning/execution ability monitoring system such as work order, plan, and performance

∙ Prevention of recurrence by identifying the cause of a problem, sharing of field data promptly and consistently, and support for expedited decision-making

ㅇ APS package Maximizes package advantages and improves production management level by reflecting and documenting high-quality results that satisfy the requirements in a short period of time in the system

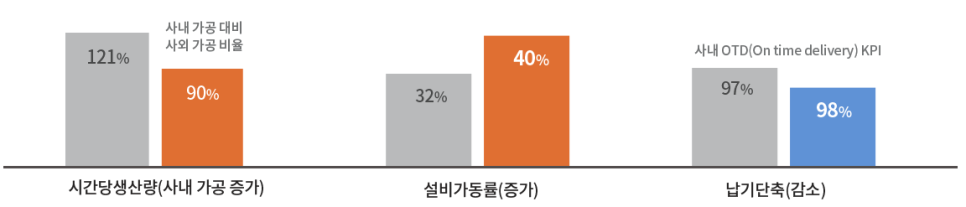

qualitative performance

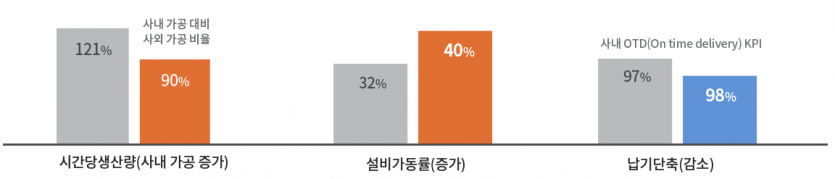

ㅇ High level of Backward and Forwarder

- Securing the ability to increase the delivery compliance rate based on actual available equipment, materials and all resources

ㅇ Visualization of future production capacity

- Visually present the company's current and future production constraints

ㅇ Efficient planning and scheduling

- Fast scheduling is possible due to the automated system, providing an opportunity for planners who depended on manual work to perform more productive tasks

- One person performs scheduling tasks that were normally in charge of 2-3 people

ㅇ Efficient communication and collaboration between departments

- By integrating and managing schedule information of all production sites, subsequent tasks affected by the change in the schedule immediately reflect the change in the plan.

ㅇ Work-in-process and raw material inventory management

- By suggesting an efficient work sequence, the level of work-in-progress can be reduced, and the date of input of raw materials is accurately calculated and reflected in the purchasing policy.

Implementation Application System

KOR

KOR