본문

Introduction purpose

ㅇ Integrated management of all activities (receiving, warehousing, inventory, picking, outgoing, etc.) that occur while managing logistics and inventory within the warehouse to improve the company’s logistics management and operational capabilities, thereby improving the useful use of management resources and improving customer service Create a supportive environment

ㅇ Efficiently operate warehouses by quickly and accurately managing all warehouse tasks (receiving, location, delivery, movement, inventory due diligence, etc.) within the warehouse and supporting real-time sharing of supply channels and inventory information.

ㅇ Improving shipment performance management: Accurate and transparent performance management by providing shipment performance management through a barcode system

ㅇ Easy to understand inventory status - Quickly explore inventory status to understand

ㅇ As production data can be accurately and quickly collected and analyzed, it is possible to prevent recurrence by identifying the cause of a problem, to share data quickly and consistently, and to facilitate decision-making.

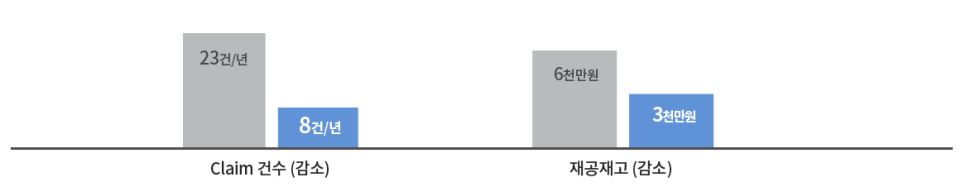

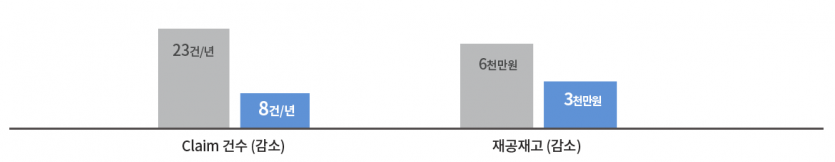

Introduction performance

quantitative performance

qualitative performance

ㅇ Delivery tracking information inquiry

- In order to check the tracking information of the delivered product, it is quickly inquired through the system inquiry, not by phone or on-site inspection, etc.

ㅇ Easy to understand inventory status

- Quickly explore the inventory status to understand the current status

ㅇ Improving shipment performance management

- Accurate and transparent performance management is possible by providing production performance management and shipment performance management through the barcode system

ㅇ Identify the cause of the problem

- Accurate and rapid collection and analysis of data in the warehouse is possible, preventing recurrence by identifying the cause of the problem.

Sharing of field data quickly and consistently and speeding up decision making accordingly

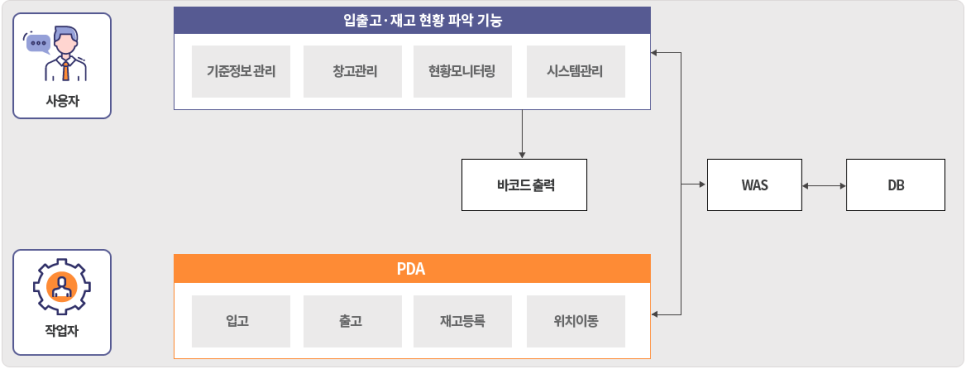

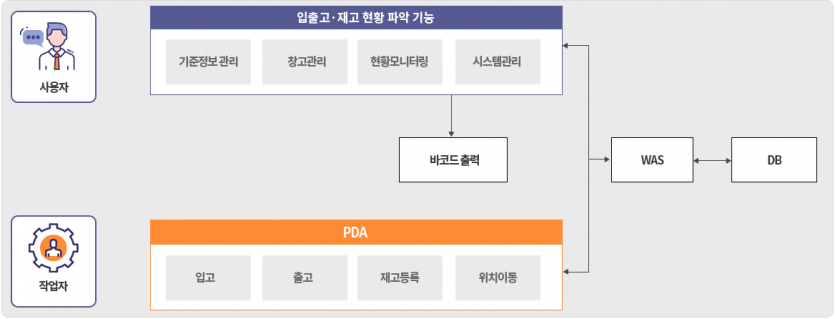

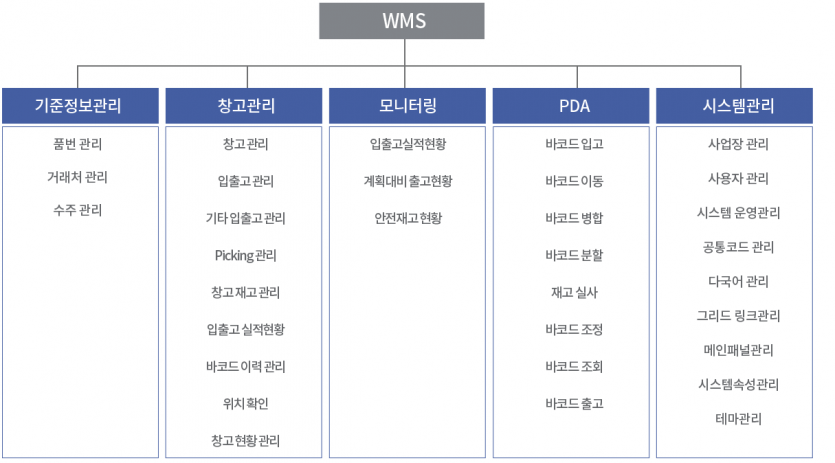

Implementation Application System

KOR

KOR