본문

Introduction purpose

ㅇ With the current management method that manually manages production history, it is difficult and cumbersome to register defects, and it is difficult to immediately respond to quality problems due to the inability to manage production history. In addition, due to the manual recording of performance data, it is difficult to manage the data due to the production process.

ㅇ It is difficult to respond to changes in the work environment, and the current management method of manually giving work instructions to the site and distributing drawings printed on paper to workers. It takes time to check whether there is an order, and there is a loss due to redistribution of work orders and drawings.

ㅇ It is difficult to systematically monitor the situation at the production site, and it is difficult to control the quality of the measured values.

ㅇ Due to the lack of coding for each product and process, it is difficult to track the lot when a defect occurs, so it takes a lot of time to analyze the cause of the defect and set up measures to prevent recurrence.

ㅇ Due to the nature of the medical device manufacturer, it is necessary to present evidence that it satisfies various domestic and international legal regulations. However, due to the absence of a management system, the person in charge collects and prepares all the supporting data manually, resulting in many problems due to reduced work efficiency and low data reliability.

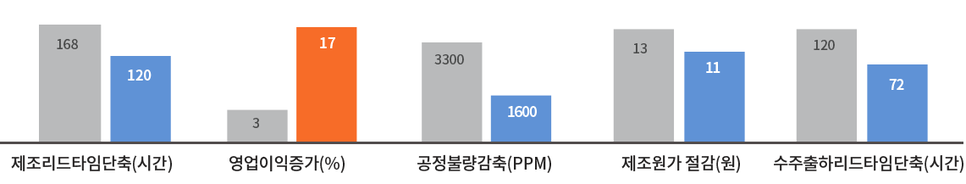

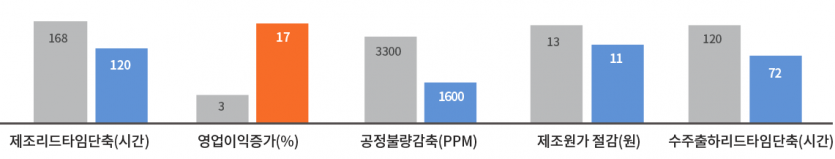

qualitative performance

ㅇ Minimize loss of production time that may occur due to equipment failure by real-time monitoring of the production status and establishing an environment that can respond immediately in case of failure

ㅇ It is expected that performance information will be aggregated based on performance data obtained through KIOSK and PDA in an environment where the existing performance aggregation was managed manually, securing high-reliability data and result values, and shortening the time for performance input.

ㅇ Accurate and rapid collection and analysis of production data becomes possible, so decision-making is expedited by inquiry/output and monitoring of various reports

ㅇ Improving production and shipment performance management

- Accurate and transparent performance management is possible by providing production performance management and shipment performance management through the barcode system

ㅇ It is expected that the real-time and accurate information sharing system will be established, which will increase productivity and increase corporate profits.

ㅇ Fast and consistent sharing of on-site data and expedited decision-making

ㅇ It is possible to monitor the flow and management activities within the production site such as production, inventory, defects, and materials in real time to ensure transparency. Based on the acquired data, better management is possible

ㅇ Inquire about finished product production tracking information

- In order to check the tracking information of manufactured products, quickly inquire through system inquiry, not by phone or on-site inspection

ㅇ As production data can be accurately and quickly collected and analyzed, it is possible to prevent recurrence by identifying the cause of the problem.

ㅇ Fast and consistent sharing of on-site data and expedited decision-making

ㅇ Since the data obtained from the system is stored in a DB, it becomes a data asset that can be used as a basis for future business expansion and material purchase.

ㅇ Provide company-wide manufacturing status information to secure global medical device regulatory responsiveness through the introduction of Global MES in the medical device industry, connect design-manufacturing-quality response, and secure visibility between production/material/quality/purchase infrastructure Securing efficient management of Q(Quality)/C(Cost)/D(Schedule) from the inventory linkage point of view

ㅇ ㅇ Secure CSV (Computer System Validation) and respond to Food and Drug Act due to the characteristics of medical device manufacturers that must comply with FDA and various domestic and foreign legal regulations

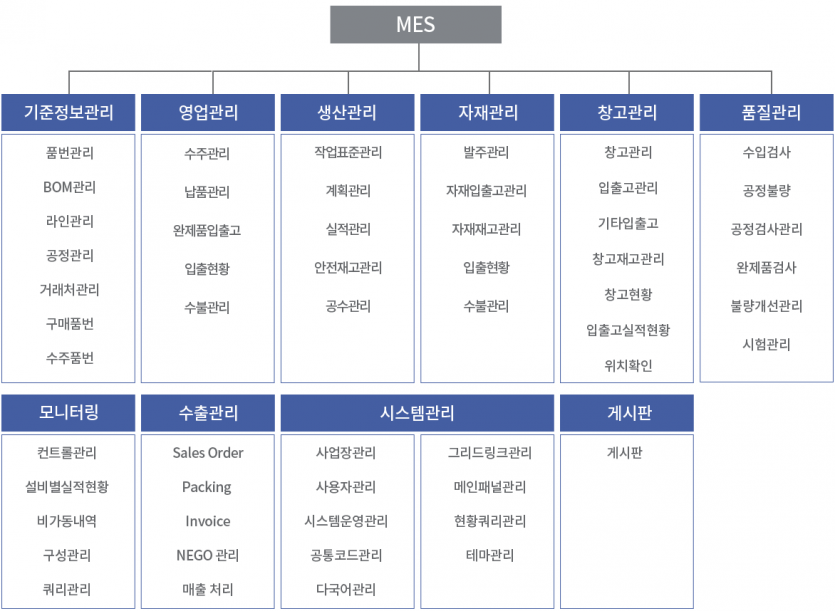

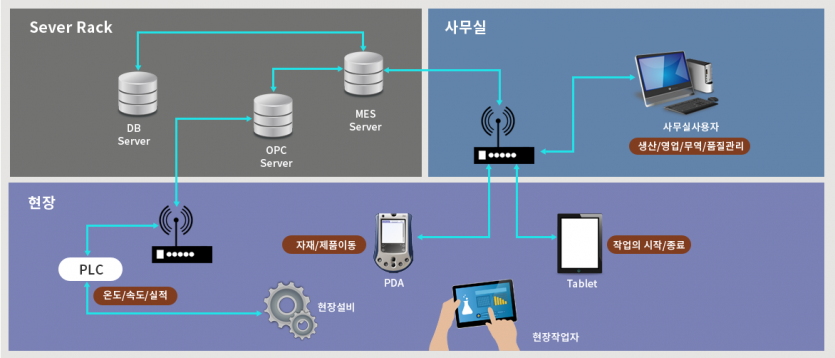

Implementation Application System

KOR

KOR