본문

Introduction purpose

Improvement of work efficiency and convenience through identification of shortfalls in assembly lines and immediate identification of material supply/demand/stock status, and improvement of management efficiency by identifying overall tasks such as material flow and inventory in real time

As we shift from outdated management techniques that used to be managed manually to company-wide management, we can quickly acquire integrated and consistent information to perform real-time tasks and manage the entire business in an integrated way.

Real-time monitoring of production process status, material supply and demand, inventory status, and quality status, and monitoring the flow and use of various resources in the company

When material is received, it utilizes the warehousing history and barcode tag attached to the real thing to identify warehousing and inventory and prevent inventory loss due to long-term storage

Through movement and location management of received materials and stock, workers can quickly identify the work order and secure the ease of grasping materials and stock

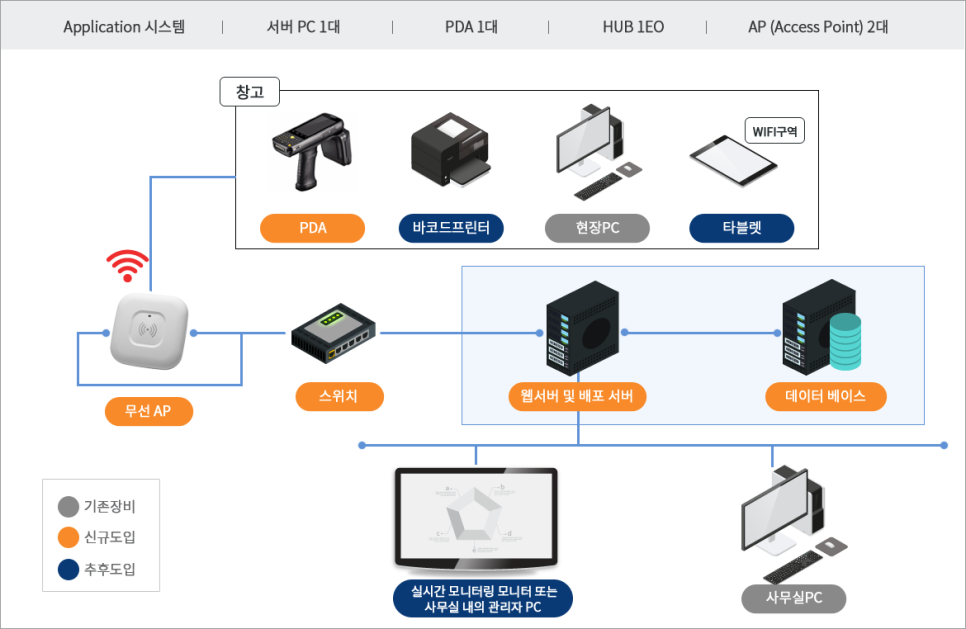

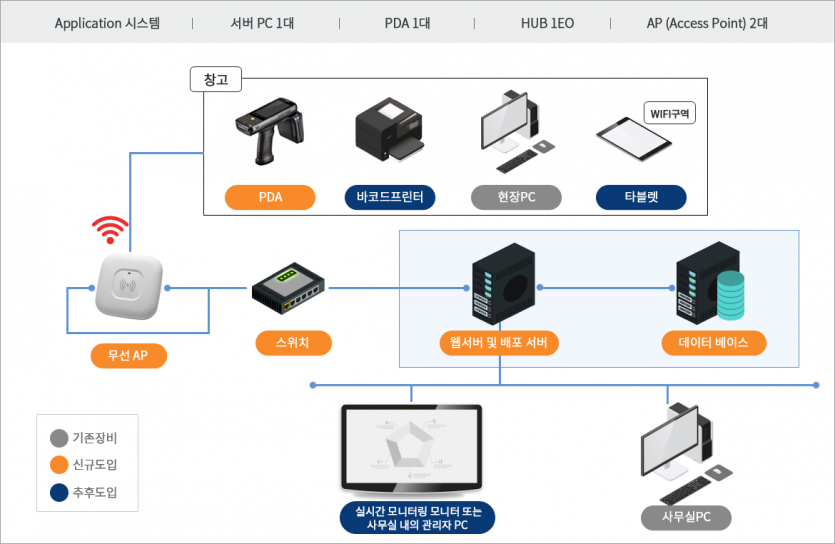

Introduction equipment

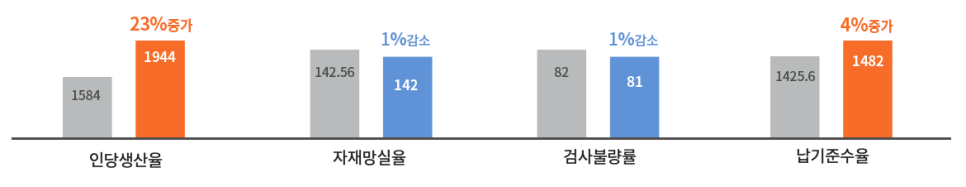

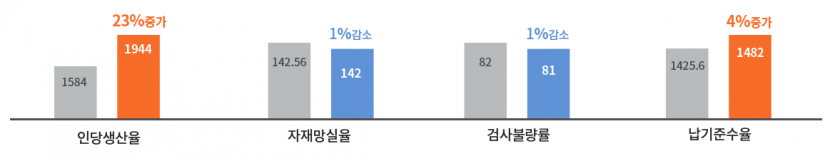

Introduction performance

Quantitative performance : Annual increase in production rate per person, improvement of inventory status improvement

qualitative performance

- By establishing a real-time accurate information sharing system, it has the effect of increasing productivity and increasing corporate profits.

- Real-time monitoring of inventory, movement, location, material flow, and management activities is possible to ensure transparency, and by creating an open work environment, it is possible to easily identify work progress and problems. Enables better management

- Reduction of work hours (3~4 hours/day) by performing efficient outsourcing work management by improving work such as outsourcing work log and construction completion calculation

- Real-time production performance management, warehouse monitoring, and inventory management system enable visual office and production site management regardless of management location

- It is possible to have an open and transparent work environment by breaking away from the work center that is dependent on the person in charge.

- The frequently changing information system is a good opportunity to consign to an external professional company and focus on the company's core business.

- By building a system that can control/manage a series of processes for warehouse management and inventory management flow, the data obtained can be used to increase the efficiency of work, such as providing statistical data on the location of materials and inventory, and Human resource management becomes possible

- Since the data obtained from the system is stored in a DB, it becomes a data asset that can be used as a basis for future business expansion and material purchase.

- Fast and consistent sharing of field data and speeding up decision making.

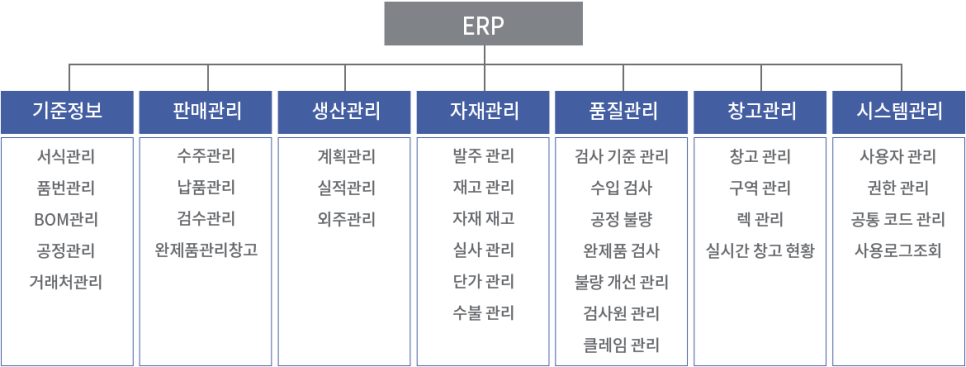

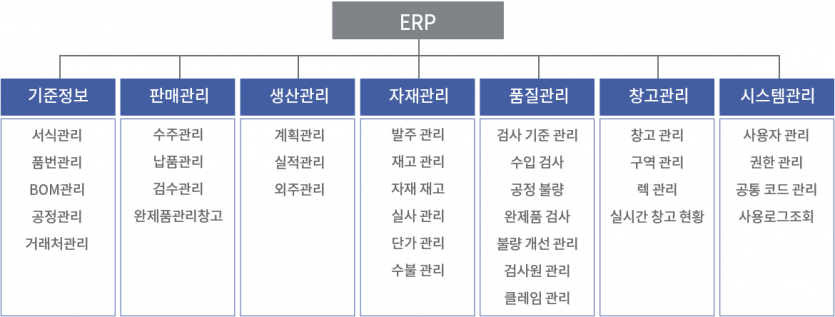

Implementation Application System

KOR

KOR